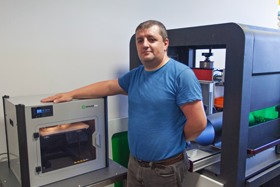

Another company joined the group of owners of industrial 3D VSHAPER PRO+ printer. B-4 Association, operating on the market for almost 20 years, cooperates with the manufacturer of underwater scooters looking and acting like props from movies about agent 007. The institution, based in Rzeszów, deals with comprehensive support for projects in the field of education, development and innovation. It also focuses its activities on broad business consulting and auditing. B-4 Association apart from the current support in production processes, also conducts design research aimed at developing a new prototype of the SEACRAFT underwater device.

SEACRAFT underwater scooters are designed for recreational and technical diving at a depth of up to 150 m. It is an additional element of the diver’s equipment, significantly increasing the speed of moving underwater, and thus – increasing the range of diving. The use of 3D printing in the design process has made it possible to develop innovative solutions that are very difficult to implement using conventional methods. The device is constantly tested by many world-famous divers taking part in the exploration of caves and wrecks, both in salt and fresh water. An interesting fact is that the tests of scooters take place on the lagoon in Solina (depth up to 60m) and in Tarnobrzeg Lake.

One of the elements of the scooter realized with the use of VSHAPER PRO+ machines is the power supply for the underwater scooter. The B4 Association has the task to develop, test and prepare electric cells of appropriate efficiency. A dedicated base is created for the production of batteries, which is then filled with cells. The next step is to weld the first layer of cells prepared in such a way. Then the next layer of cells is laid, which are held in the right position by means of special clamps.

„Until now, it has taken several working days to complete the base: to develop the base in a CAD program, to prepare the production in the appropriate CAM program, to wait for the “free period” in the CNC milling machine work or to queue the task, to milling the base and, if there is even a minimal change, to restart the whole process. Now, with VSHAPER PRO+, we can design and manufacture batteries of different capacities on the spot. In addition to the base, we also make templates on the 3D printer to keep the cells in a constant position during the welding process. The accuracy of the print allows us to produce components that are like blocks and do not require any additional processing” – says Albin, a representative of the B4 Association.

A measurable benefit of using the VSHAPER PRO+ device is the use of rapid prototyping technology, which allows you to make shape corrections and quick design development of a new template and its implementation. Thanks to the high precision of the models made on the VSHAPER PRO+ machine, the template used to hold the cells in a fixed position during welding can be assembled from separable elements like blocks. This simplifies the process of disassembling the template after the welding process is completed. The manufacturer of SEACRAFT underwater scooters saves time and resources. Thanks to, among other things:

• no need for time-consuming programming on CNC machines in order to make templates;

• easy and fast process of assembling and disassembling templates;

• quick execution of the redesigned model on a 3D printer.