A compact system of advanced 3D printing, designed for users who expect fast results while maintaining industrial standards.

Kinematic solutions known from the laser cutters enable reliable operation for many hours with efficient printer head movement and printing accuracy.

Stability of work and precision obtained thanks to high-class servomotors, ball screws and linear guides, allows for accurate and repeatable prints.

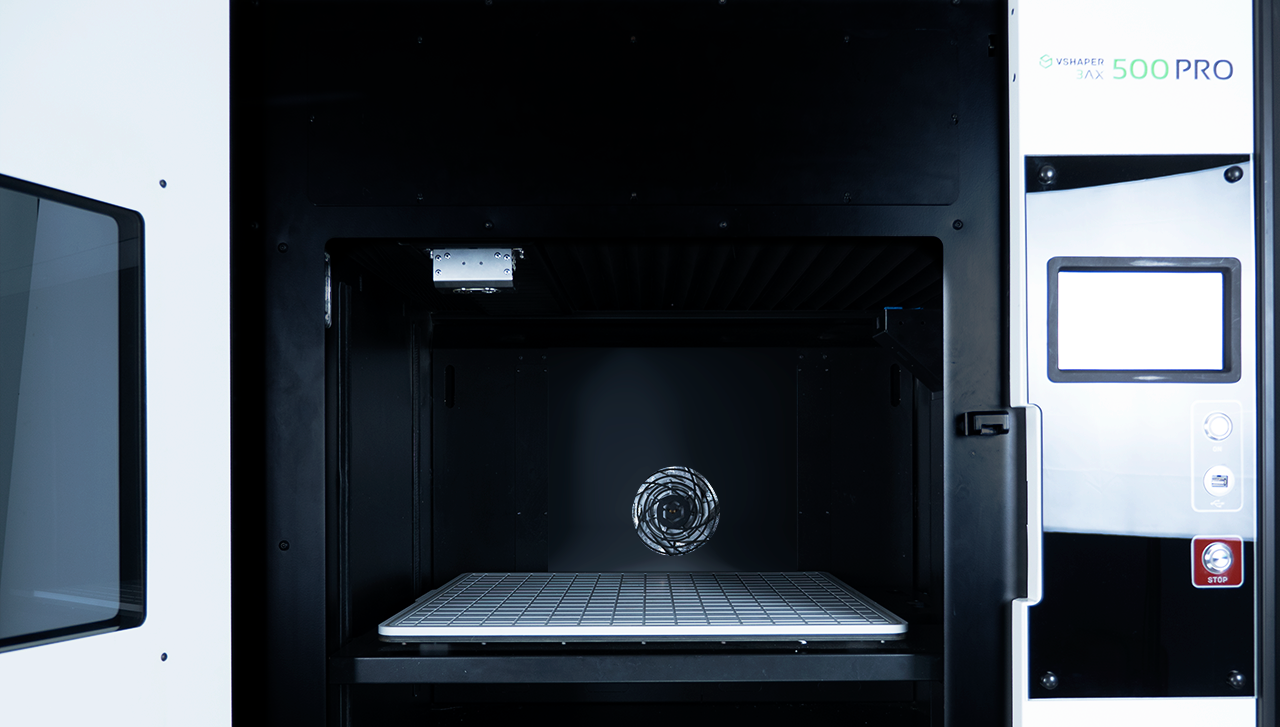

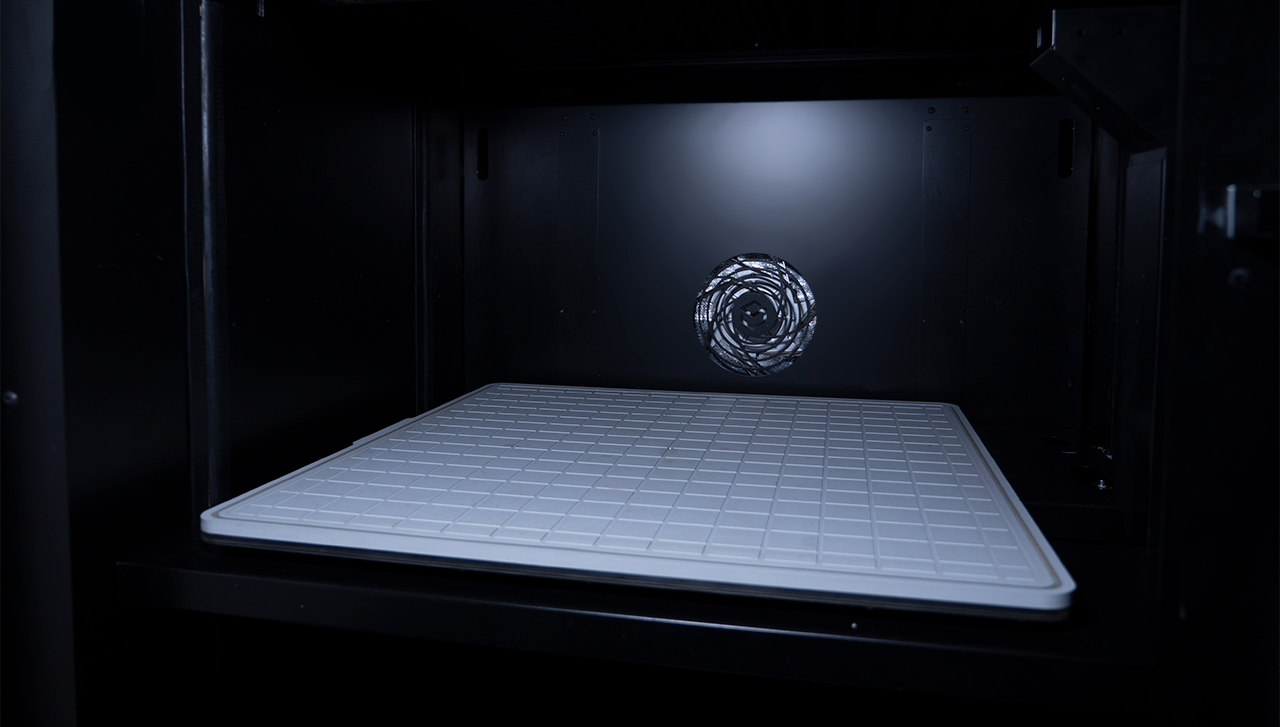

The actively heated working chamber is particularly appreciated by users as it provides the perfect conditions for the processing of a wide range of commercially available polymers, enabling satisfactory printing.

Safe and reliable closed system reduces the amount and harmfulness of gases emitted during printing.

The patented design of the working bed ensures optimal adhesion of the first print layer and comfortable exchange of the surface on which the print takes place.

Automatic, matrix calibration of the print bed is a guarantee of better quality and accuracy of the printed model.

A high-performance extruder, with direct material feeding, processes polymers reaching temperatures up to 450°C.

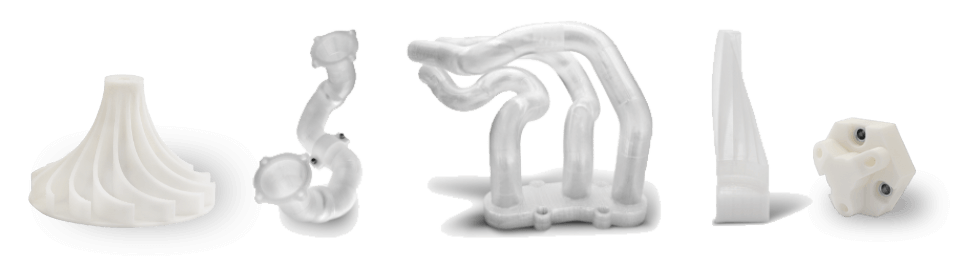

Thanks to the use of the two-nozzle system, it is possible to use two different materials in one process.

Learn about the Device Parameters

VSHAPER 500 PRO is a 3D printer for industrial use. It prints a wide range of materials from high-temperature PEEK and demanding, flexible TPU, through advanced polyamides to basic materials. Thanks to the application of a two-nozzle head, it can use two materials in one process - a main and a support or two main materials, which releases a wide range of possibilities of this 3D printer when processing complicated models.

Define business requirements and let us prepare an offer best suited to your needs.