An efficient specialized device in the segment of medical 3D printers is a response to the growing demand of the modern medical sector.

Get a quote

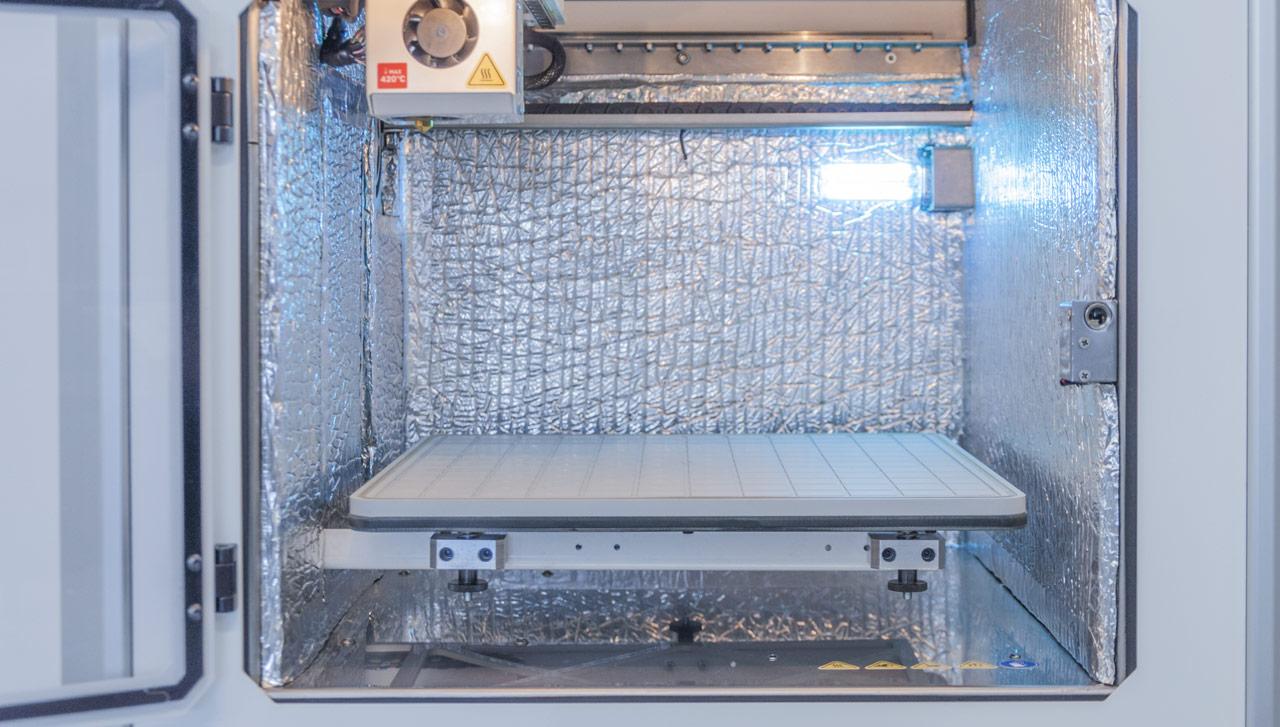

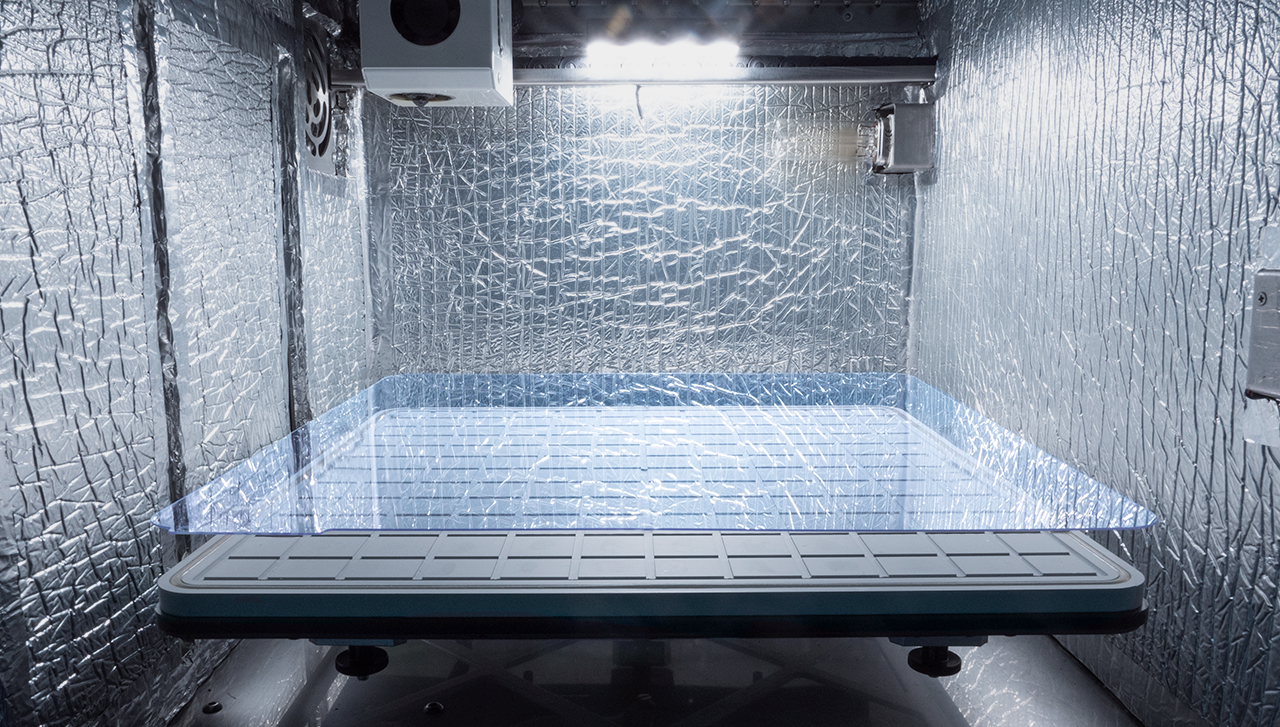

The design enables sterilization of the chamber and the model with UV rays at every stage of the printing process.

It provides the right environment for creating precise 3D printouts intended for medical purposes.

The temperature control inside the machine guarantees the most optimal heat value of the printing environment.

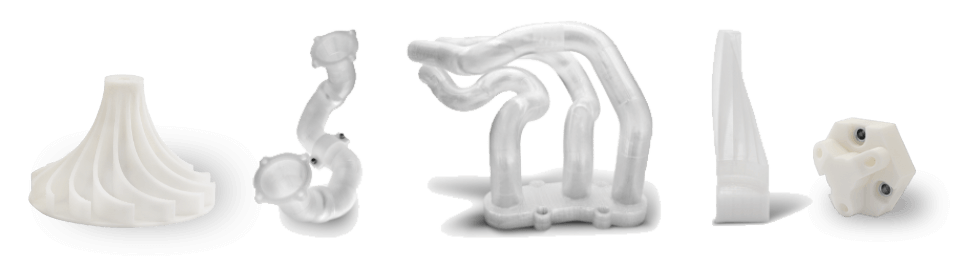

It allows for the use of an industrial grade biocompatible polymers, such as PEEK - material dedicated to implantological applications.

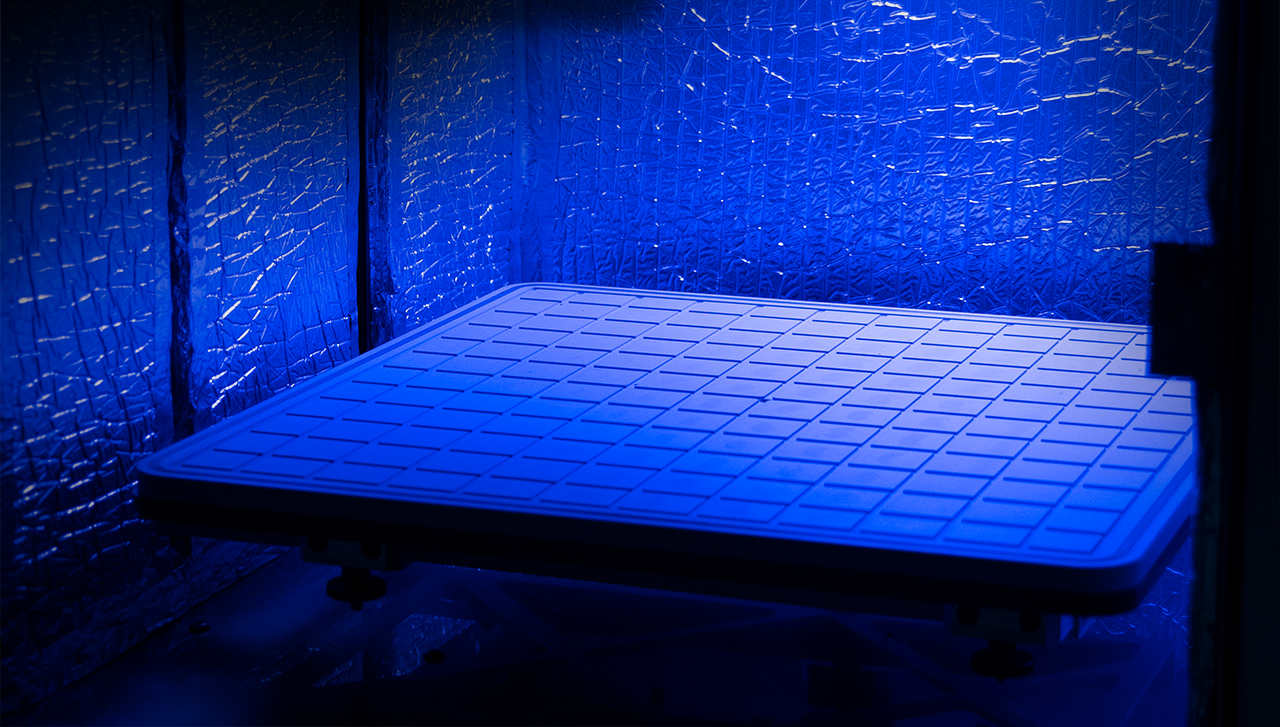

The printer bed with the option of an easy replacement of the surface on which the print is performed, moreover it does not require positioning.

It enables the tight adhesion of the first layer and convenient removal of the model after the printing process is completed.

Models printed in a controlled environment of an actively heated build chamber disntiguish themselves with high dimensional accuracy and mechanical strength.

The safe-to-use enclosed chamber system, additionally minimizes the amount of harmful gases emitted during printing.

Learn about the Device Parameters

Maximum print temperature:

300°CNozzle diameter:

Standard: 0.4 mm (optional: 0.25, 0.6, 0.8, 1.0)Filament diameter:

1,75 mmRecommended materials:

ABS, ASA, PC-ABS, PC, PA6, PA12, PA+GF, PA+CFFilament feeding accuracy:

1 μmMaximum print temperature:

300°CNozzle diameter:

Standard: 0.4 mmFilament diameter:

1,75 mmRecommended materials:

ABS, ASA, PC-ABS, PC, PA6, PA12, PA+GF, PA+CFFilament feeding accuracy:

1 μm3D printers are increasing participation in medical applications. The VSHAPER 270 MED is a machine tailored for medical applications. Thanks to the implemented solutions such as UV light sterilization, medical grade materials construction, and the possibility of processing biocompatible PEEK - it will perfectly fit into medical and veterinary applications

Define business requirements and let us prepare an offer best suited to your needs.