Customers, who benefits from VSHAPER 3D Printing solutions

01

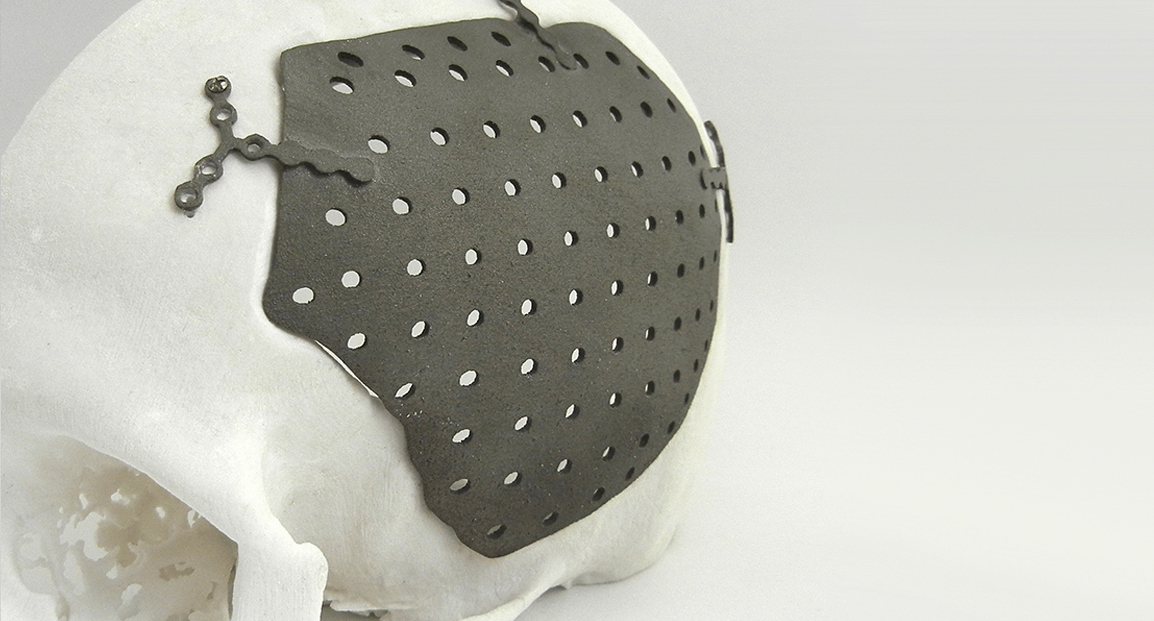

Additionally, biocompatible thermoplastic materials, used for damaged bone parts printing, show temperature stability among changeable conditions of the body environment. That is why it does not cause such kind of inconvenience to the recipient.

Get a quote

02

Similar Prints help doctors in a deeper understanding of the structure of the organ, figure out the location of the tumor or the distribution of blood vessels. Thanks to that procedure, the real surgery may proceed much faster and in a safer way.

Get a quote

03

An additional advantage of such a solution is the reduced costs of storing medical components in appropriate conditions and the costs of logistics.

Get a quote

04

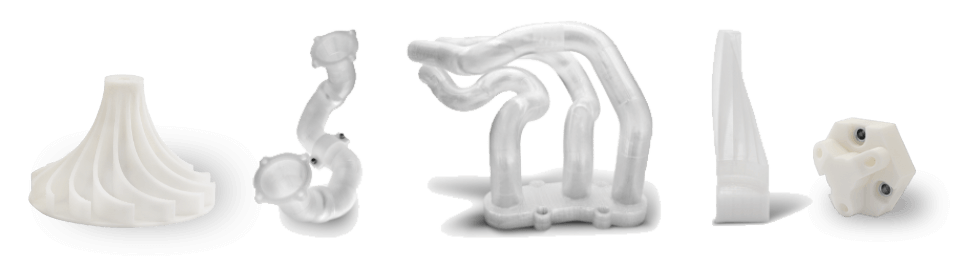

Thermoplastic Printing Technology allows the creation of parts with sections such as internal cavities and lattice structures that help reduce the weight of the elements without compromising their mechanical performance.

Get a quote

05

3D Printing gives the possibility of reconstruction of machine parts damaged as a result of its use, where servicing is time-consuming and sometimes even impossible.

3D printers that are able to print with many materials during one printing process allow the production of parts with different properties within one structure.

Research shows that during additive manufacturing

less material needed to produce a single part

lower production cost

part weight and project implementation time are reduced

Define business requirements and let us prepare an offer best suited to your needs.

Get a QuoteRead more about how 3D printing can be used effectively in industry, and learn about the value of 3D printing technology in various industries and applications.

Find out more about the 3D printing service in the food industry. Learn about the implementation of 3D printing at Frezmet, how 3D printing replaced the milling machine. What were the goals of the collaboration, what problems were encountered and how were they solved? Read now.

VSHAPER solutions guarantee precise printing of individual elements that together form a functional mechanism. The precise 3d printout with given parameters requires mastered wisdom about FDM technology key aspects. Innovative VSHAPER solutions guarantee efficient control of settings of printing conditions and investigation of printed filament dynamics. The ability of precise 3d printing of individual elements of different […]

The Fakro company which is present on polish and global markets, the worldwide leader in skylights and attic stairs production, joins to the list of VSHAPER users – the producer of industrial 3D printers. In 2019 Fakro’s Development and Research department engineers decided to enrich their machinery park with a new industrial 3D printer. .