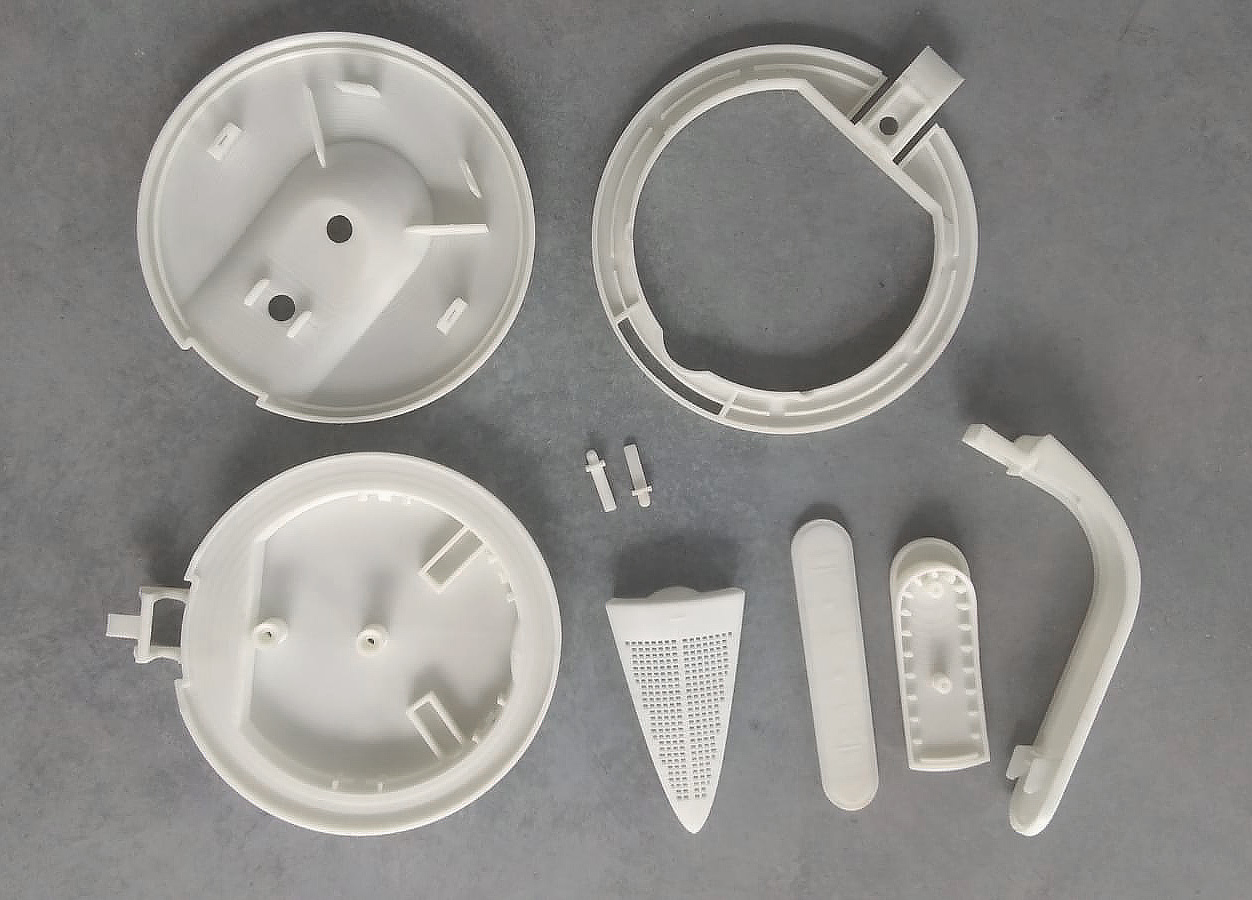

VSHAPER solutions guarantee precise printing of individual elements that together form a functional mechanism. The precise 3d printout with given parameters requires mastered wisdom about FDM technology key aspects. Innovative VSHAPER solutions guarantee efficient control of settings of printing conditions and investigation of printed filament dynamics. The ability of precise 3d printing of individual elements of different sizes and complexity, forming a functional mechanism, was a key factor for the INVEST company.

The perfect match of 3d printed parts.

The 3d printing in FDM technology allows the creation of complex shapes with a degree of design freedom, which is unavailable with traditional manufacturing methods. Thanks to its smooth production implementation, it gives a real alternative to small and middle-lot production and highly adjusted parts such as prototypes, personalized devices, or complex structures.

VSHAPER 3d printing engineers analyzed the INVEST project and selected the appropriate process specification. The mechanical parameters of the filament may vary depending on the changes in the thermal profile of the printed material and the skillful handling of the heating and cooling temperature in the machine’s working chamber. The printing technology has been selected to precisely reproduce even the smallest elements of a given project.

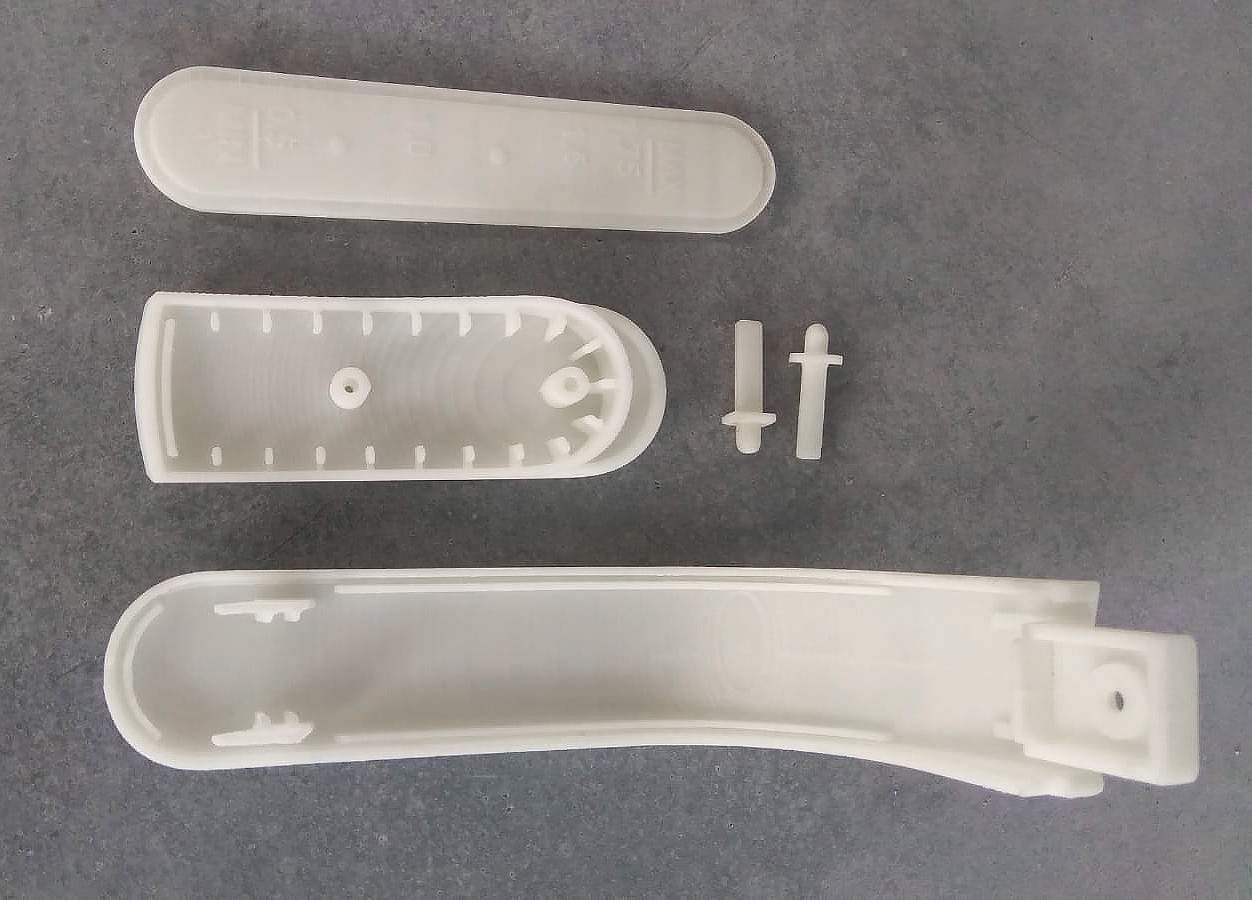

Support structures – does my model need them?

The lean angle of the given surface, within the FDM process, may be achieved by a slight layer shift. It means that elements with angles up to 45° allow printing without support structures. However, if the part’s lean angle is greater than 45°, or includes features such as bridges and surfaces that stick out more than 5 mm, support structures are required. The main purpose of the supports is to assure the precise geometry of the printed model and avoid paths deformations or delaminations.

The supports allow us to accurately reproduce the geometry of the model and fully control the given form. The strict sticking of filament to the supports guarantee precise printing of individual elements, that when assembled create a working mechanism. What may cause problems is to remove them.