Customers, who benefits from VSHAPER solutions

01

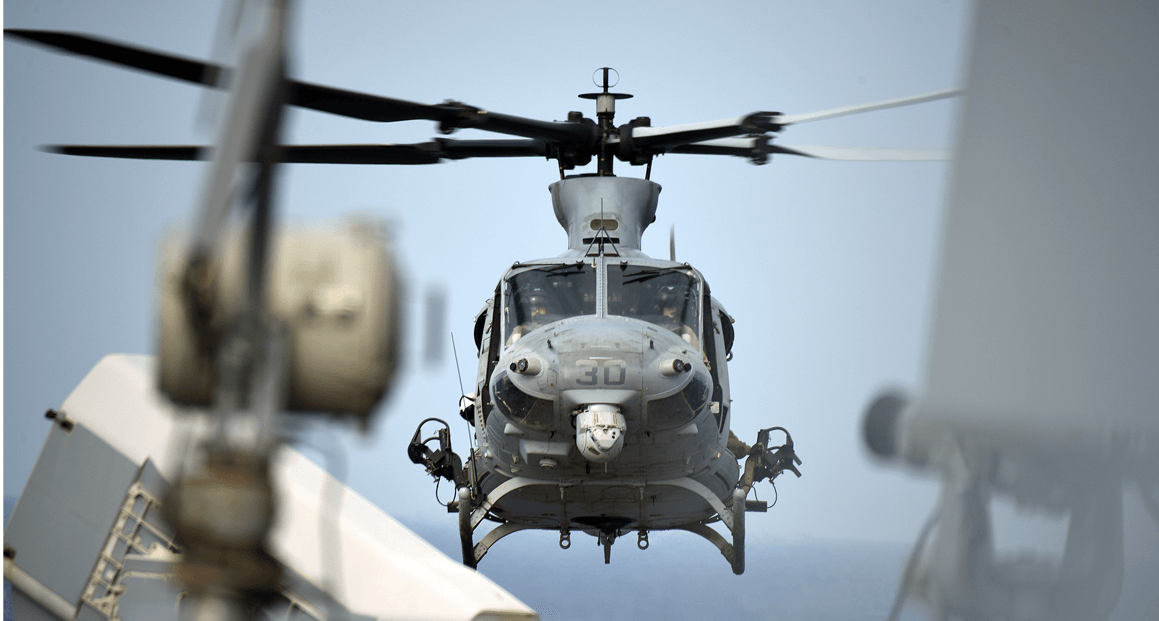

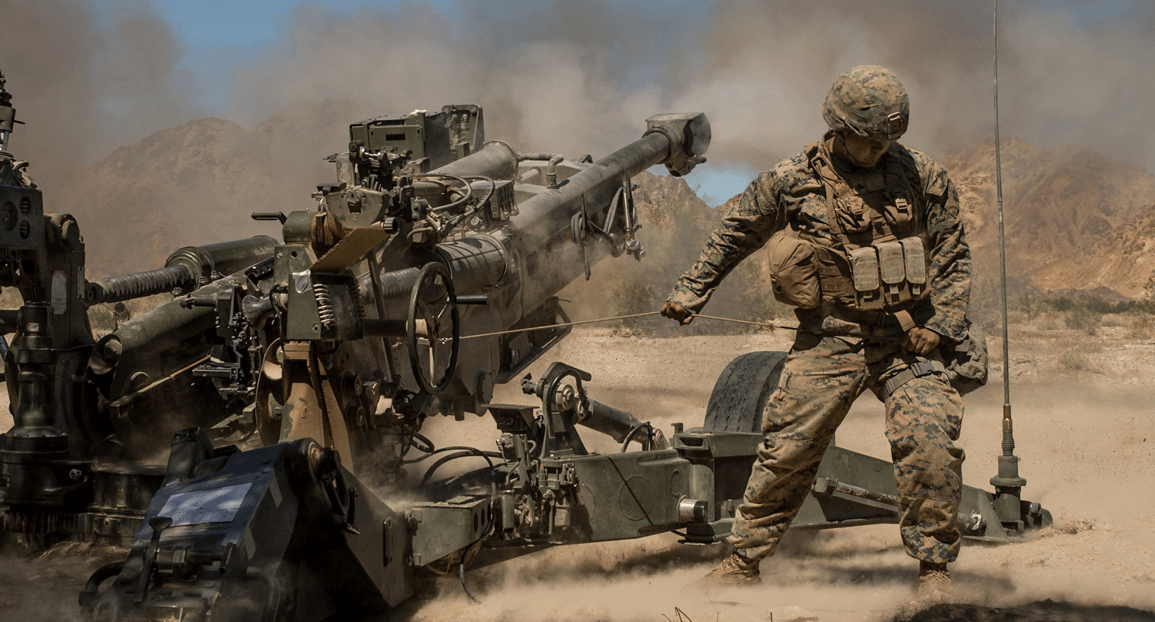

War zones, as well as on the sea as on the land, are an example of a situation where often for a long time, soldiers are not able to renew their inventory. With 3d printing technology obtaining the needed parts on the spot for the service purposes of equipment means the transportation of required material.

Get a quote

02

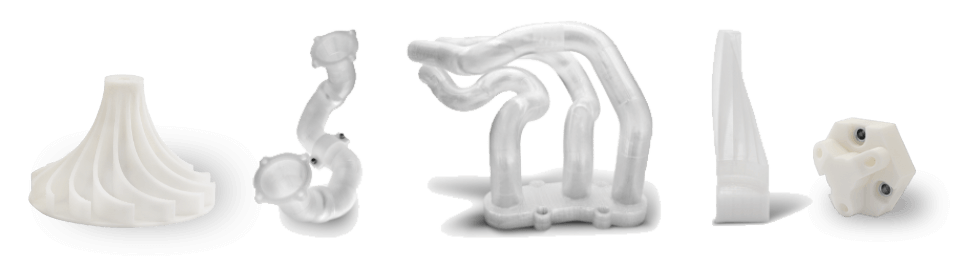

In general, the production of elements by 3D Printing drastically eliminates the amount of necessary tooling and reduces the lead time.

Get a quote

03

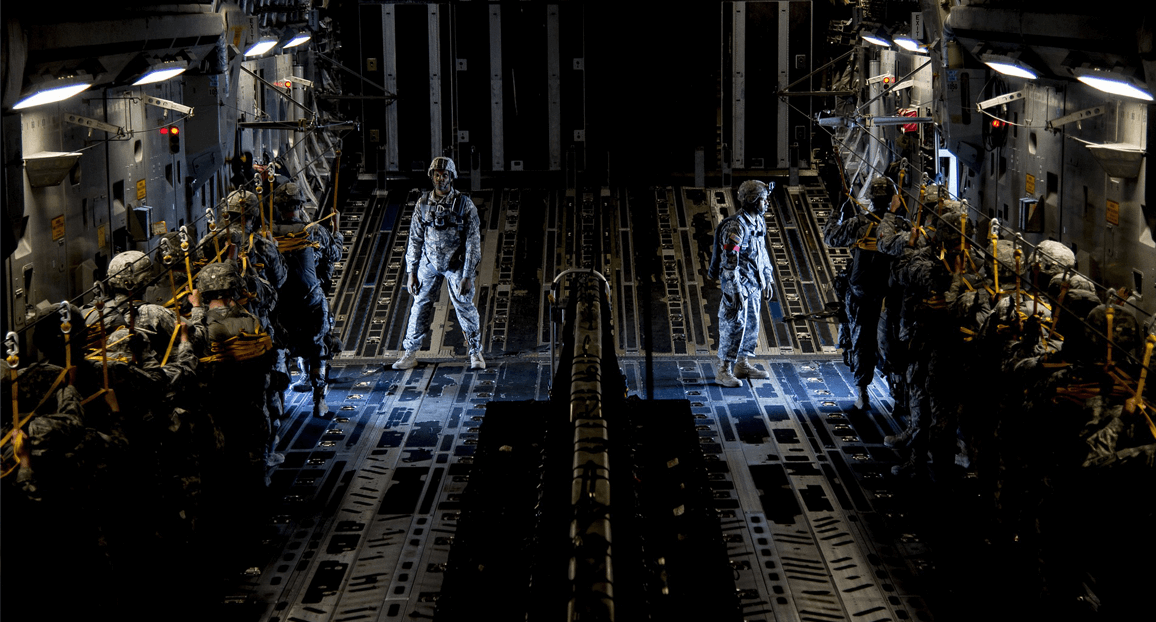

Polymers do not just lower the weight of stuff – they increase the agility as well as user safety.

Additionally – because the combined parts, which initially may consist of a few components, the printed version may be made with fewer components or in one piece, so the manufacturer can reduce the whole amount of produced parts.

04

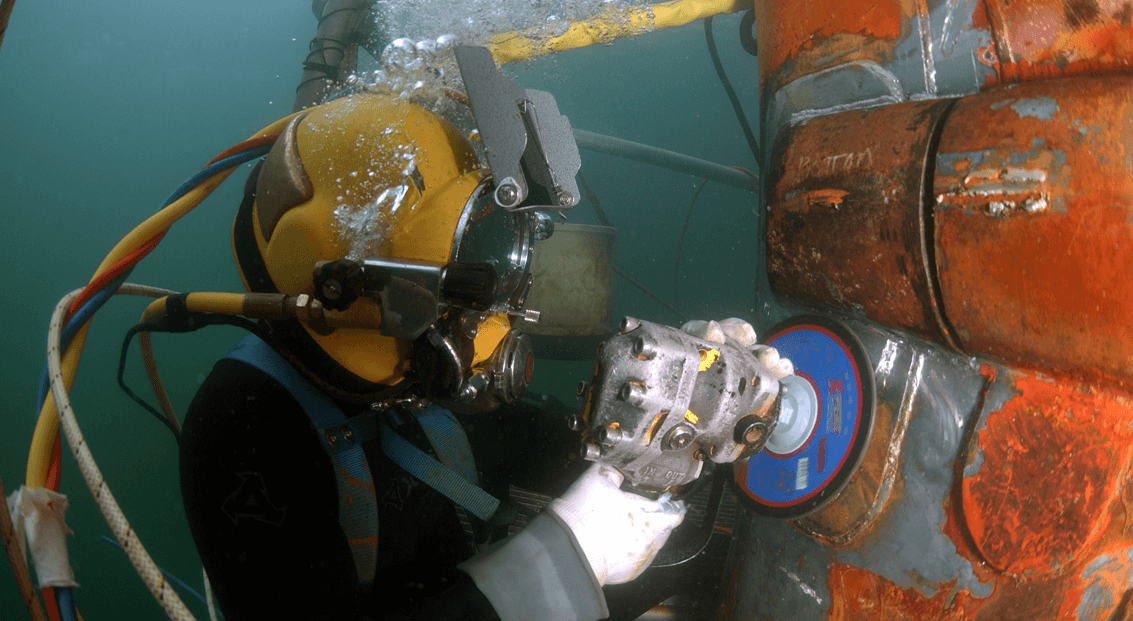

These possibilities would enable engineers with processing more types of repairs on site, reduced inventory requirements, and uncertainty related to equipment levels.

Get a quote

05

Nanocomposites (polymers filled with nanoparticles, such as carbon nanotubes, graphene, etc.) increase fracture toughness and electrical conductivity.

This additional functionality can find its role in detecting deformation or damage. Other additives may increase resistance to ultraviolet light and heat or prevent oxidation.

06

Thanks to plastics, manufacturers and designers can create virtually any color or finish during the production process and eliminate the need for costly secondary painting or coating required otherwise by metal parts.

What’s more, the color of the finish on the plastics will not wear off as a result of the wear process.

Today’s advanced 3D Printed polymers are extraordinarily durable and can outperform comparable metals in terms of resistance to heat, chemicals, moisture, and impact.

less material needed to produce a single part

lower production cost

part weight and project implementation time are reduced

Define business requirements and let us prepare an offer best suited to your needs.

Get a QuoteRead more about how 3D printing can be used effectively in industry, and learn about the value of 3D printing technology in various industries and applications.

Find out more about the 3D printing service in the food industry. Learn about the implementation of 3D printing at Frezmet, how 3D printing replaced the milling machine. What were the goals of the collaboration, what problems were encountered and how were they solved? Read now.

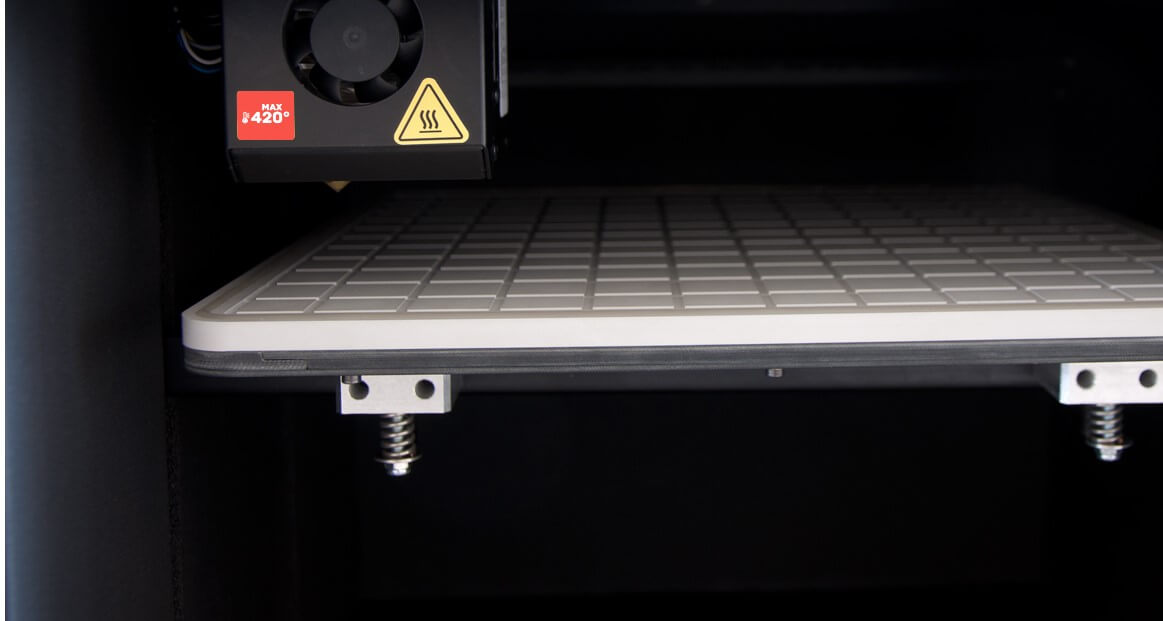

VSHAPER solutions guarantee precise printing of individual elements that together form a functional mechanism. The precise 3d printout with given parameters requires mastered wisdom about FDM technology key aspects. Innovative VSHAPER solutions guarantee efficient control of settings of printing conditions and investigation of printed filament dynamics. The ability of precise 3d printing of individual elements of different […]

The Fakro company which is present on polish and global markets, the worldwide leader in skylights and attic stairs production, joins to the list of VSHAPER users – the producer of industrial 3D printers. In 2019 Fakro’s Development and Research department engineers decided to enrich their machinery park with a new industrial 3D printer. .