3D printer software is one of the most important elements responsible for the quality, efficiency and capabilities of prints. There is a lot of 3D printer software on the market, and the choice should depend on the skills of the operator and the type of prints to be made.

Printer software is necessary to properly prepare the 3D file and to print the model with the set parameters. The software converts the CAD model file into Gcode, i.e. the model is cut into layers with settings adapted to the specific material, printer and parameters.

Choosing good printing software is as important as choosing a proven 3D printer model. Most often, software can only be used on specific printer models. The most important features of good 3D printing software: the number of supported file formats, the ability to edit files in the system, intuitive interface, predefined parameters for filaments, optimisation of prints using various functions.

3D printing software should support the most popular file formats used for 3D CAD design. The most common formats are STL, OBJ, PLY and others.

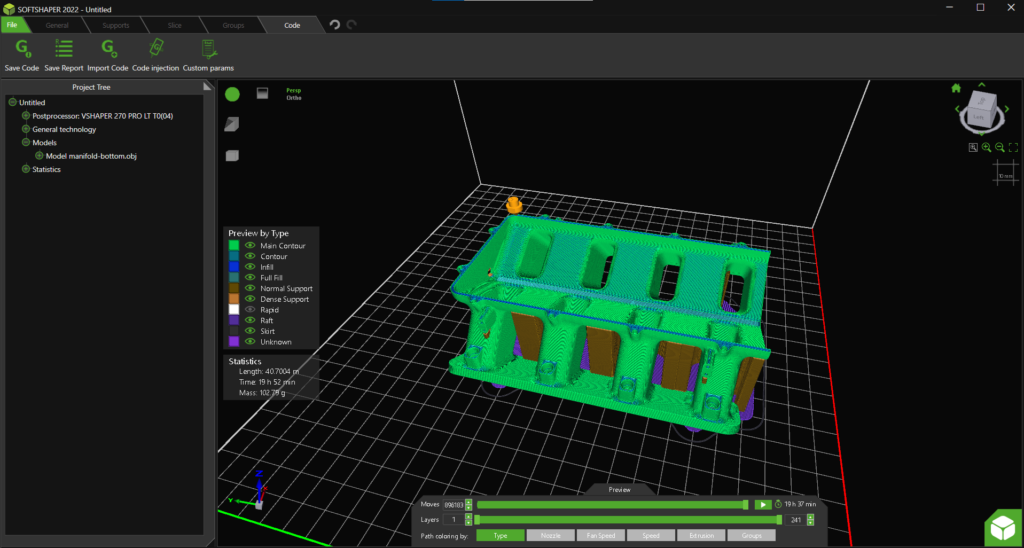

The software interface is very important for comfortable and intuitive use. The clarity of the options and the transition path from uploading a file to printing should be simple and understandable, even for a person using the system for the first time. The work in SOFTSHAPER is organised by simple confirmation messages.

This function allows individual areas within a specific layer to be strengthened. Using this function, a part of the model can be strengthened and the print time will not increase as much as when all layers are thickened. The grouping system allows groups to be defined freely. Highlights of the system: multiple groups on one layer and selective groups. To make the user’s work even more efficient, individual layers with different thicknesses are marked with different colours. One of the few software features that has been implemented is SOFTSHAPER.

3D printer software most often also provides a support module. This allows the user to modify the support structures of the model independently, regardless of the chosen material. Supports can be made from the model’s native material or from materials that can be dissolved in specific solutions. The user can parameterise the type of support infill (linear, square, hexagonal), the minimum angle of structure generation, infill density, XY offset from the model walls.

In the 3D printing software, SOFTSHAPER, it is possible to generate supports automatically or manually.

In 3D printing software, it is necessary to have the option of setting the print speed and varying it in different parts of the model. This allows the print to be produced accurately. Individual layers printed at the correct speeds are much more accurate, without defects in the print.

3D printing software should have a function to prepare the model for inserts such as screws, nuts and others to be printed. This is a very useful tool in almost every industry. It helps to increase the durability and longevity of the printed part by installing them after printing by pushing or screwing them into a pre-designed hole. Use the inserting function to join 2 or more printed parts together or to create a threaded hole for a fastener.

The software module should have precise material processing information. The SOFTSHAPER system allows the addition, deletion and editing of parameters for printing filaments. The database contains printing technology parameters selected by specialists. In addition, it is possible to set the parameters for filaments from different manufacturers yourself. Based on the information contained in this module, the system will suggest optimal parameters for the printing process, significantly reducing the time of preparation of the printing technology and improving the quality of the print.